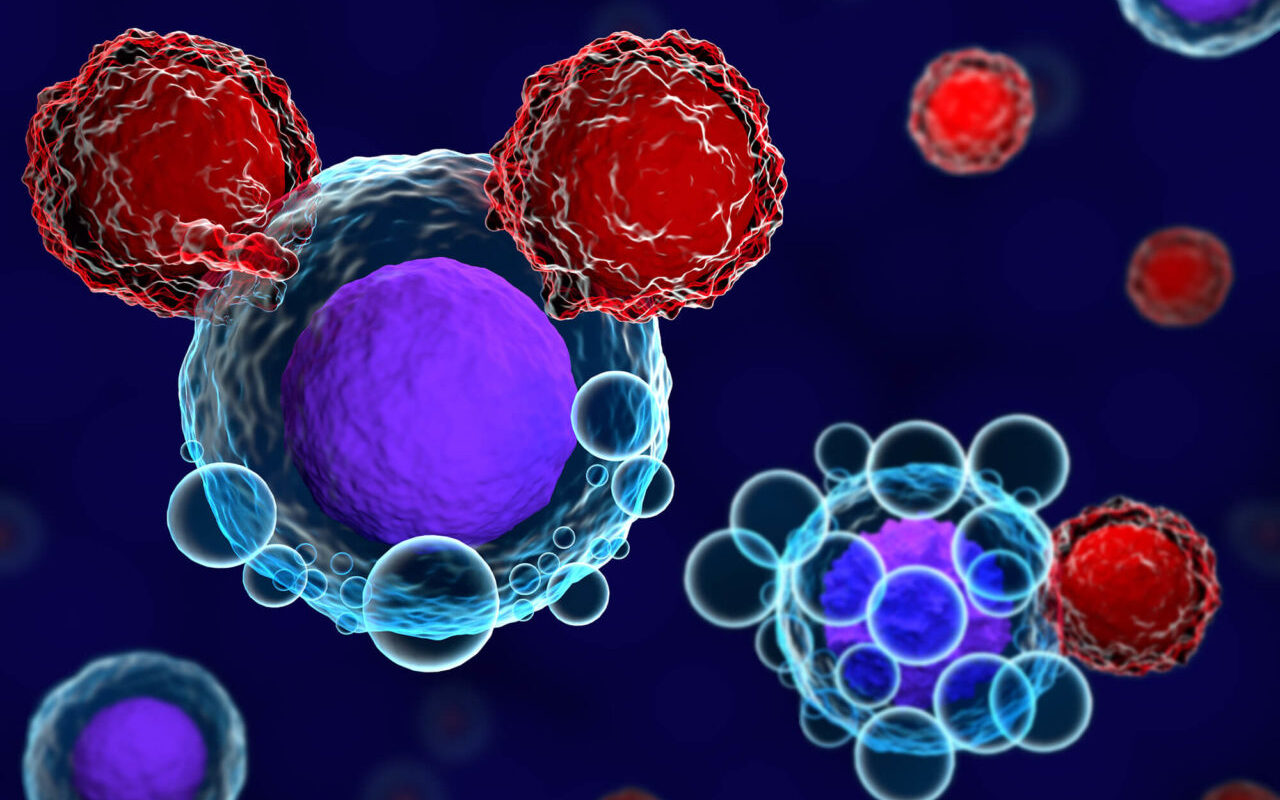

Cell therapy is an innovative type of treatment that uses a patient’s own cells or cells from a donor to treat disease or injury. By introducing new cells into the body, cell therapy aims to regenerate, replace or repair damaged tissues and restore normal function. Different types of cell therapies target a range of medical conditions like cancer, heart disease, neurological disorders and other degenerative diseases.

Current Cell Therapy Approaches

Stem Cell Therapy

Stem cells have the unique ability to both self-renew via cell division and give rise to specialized cell types in the body. There are two main types of stem cells used in cell therapy – adult stem cells found in tissues like bone marrow and umbilical cord blood, and embryonic stem cells derived from embryos. Stem Cell Therapy aims to use these self-renewing cells to generate new functional cells that can replace diseased or damaged tissue. Some common applications of stem cell therapy include treating blood disorders, heart disease and cartilage/bone damage. Bone marrow transplantation is the most established form of stem cell therapy used to treat cancers of the blood.

Immunotherapy

Immunotherapy is a type of cell therapy that boosts the body’s natural defenses by enhancing the immune system’s ability to fight cancer and other diseases. Some immunotherapy approaches involve genetically modifying a patient’s own T cells to target and destroy cancer cells more effectively. Others involve isolating certain immune cells like natural killer cells from blood and increasing their numbers for infusion back into patients. CAR-T cell therapy is a promising new immunotherapy for blood cancers that engineers T cells with chimeric antigen receptors.

Gene Therapy

Gene therapy aims to treat genetic diseases by replacing a mutated gene or adding a new gene in the body to compensate for abnormal genes. It works by delivering healthy genes into patient cells via vectors like viruses which then produce proteins that can prevent or stop disease progression. Several gene therapy clinical trials are underway for treating hemophilia, cancer and genetic disorders like muscular dystrophy. Gene editing technologies like CRISPR have further expanded gene therapy applications by enabling direct DNA modifications in living cells and organisms.

Challenges in Cell Therapy Manufacturing

While cell therapy holds tremendous potential, there are still major challenges associated with manufacturing and delivering consistent high-quality cell therapy products on a commercial scale. Here are some key manufacturing hurdles:

Cell Source Variability

Cell source variability arises due to differences in donor cells or tissues used for cell isolation. Variations in age, health status and genetic background of donors impacts the quantity and quality of cells that can be isolated. This makes it challenging to obtain large batches of uniformly standardized cells needed for large-scale production.

Cell Isolation and Purification

Efficiently isolating target cell populations like stem cells, T cells or NK cells from donor tissues requires complex manufacturing processes like enzymatic digestion, density gradient separation and immunoselection. Low cell yields or contamination risks during these isolation steps further constrain production capacities. Purifying cell subtypes remains technically difficult and resource intensive.

Cell Processing and Culture Conditions

Optimized cell processing protocols and growth conditions are vital for maintaining cell viability, functionality and expanding cells numbers during manufacture. However, factors like temperature, pH levels, nutrients and growth factors influence cell proliferation and differentiation in culture systems in unpredictable ways. Reproducibly duplicating these condition parameters across multi-site facilities presents a major manufacturing control challenge.

Product Characterization and Quality Control

Thorough cell characterization, identity confirmation and release testing for potency, viability and sterility are essential quality control steps before releasing cell therapy products for clinical use. However, developing robust and reliable analytical testing parameters for diverse cell types remains an area of active research. Matching quality standards across different manufacturing plants is also difficult to achieve consistently.

Process Scale-Up and Commercialization

Transitioning laboratory-based cell manufacturing methods to large-scale commercial production requires extensive validation, scale-up and scale-out capabilities. This involves designing scalable closed bioprocessing systems, developing standardized automated production workflows, supply chain management and meeting stringent regulatory compliance for product approvals. Considerable costs and lengthy development timelines are involved in commercializing cell therapies.

Innovations to Overcome Manufacturing Barriers

Despite production challenges, significant progress is being made through innovative technologies and infrastructure advancements:

Closed and Automated Systems

Swinging towards development of closed bioprocessing systems allows for tighter process controls and standardized operations across multiple manufacturing facilities. Automation of cell isolation, culture, harvesting and quality testing steps through robotics is helping realize higher throughputs.

Developing Improved Cell Sources

Research on induced pluripotent stem cells has generated patient-specific stem cell lines eliminating donor variability. Use of artificial scaffolds, microenvironments and 3D bioprinting aim to better mimic in vivo conditions for enhanced and scalable cell expansion. Umbilical cord blood is an abundant stem cell source that avoids ethically controversial embryonic sources.

Analytics and Continuous Monitoring

Advanced analytical tools like live cell imaging, flow cytometry, omics technologies and microfluidics are enabling real-time monitoring of critical culture parameters, cell characterization and consistent quality assessments. Continuous process verification and process analytical technology will aid scalable production.

Collaborations and Infrastructure Investments

Partnerships across companies, academic research institutes and contract manufacturing facilities are consolidating cell therapy expertise. Dedicated cell therapy manufacturing facilities and government initiatives provide infrastructure support towards developing platforms for commercial manufacturing and distribution networks.

With continued progress, cell therapy holds immense promise to revolutionize treatment for cancer, genetic disorders, organ failure and other previously untreatable illnesses. Overcoming manufacturing challenges shall pave the way towards delivering these transformative technologies to patients on a global scale.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it