With CFD, complex problems involving fluid flow, chemical reactions, heat transfer, and other related phenomena can be solved and analyzed. Let’s take a closer look at this cutting-edge field.

What is CFD?

The basic idea behind CFD is to use supercomputers to numerically solve and simulate the equations that govern fluid flow behavior. These equations, known as the Navier-Stokes equations, describe how the velocity, pressure, temperature, and other properties of moving fluid change from place to place. By breaking down a region of fluid into discrete cells and time steps, CFD allows engineers to witness flow phenomena using simple calculations.

Applications of CFD

CFD finds applications across many industries where understanding fluid flow is important. Some key uses of CFD include:

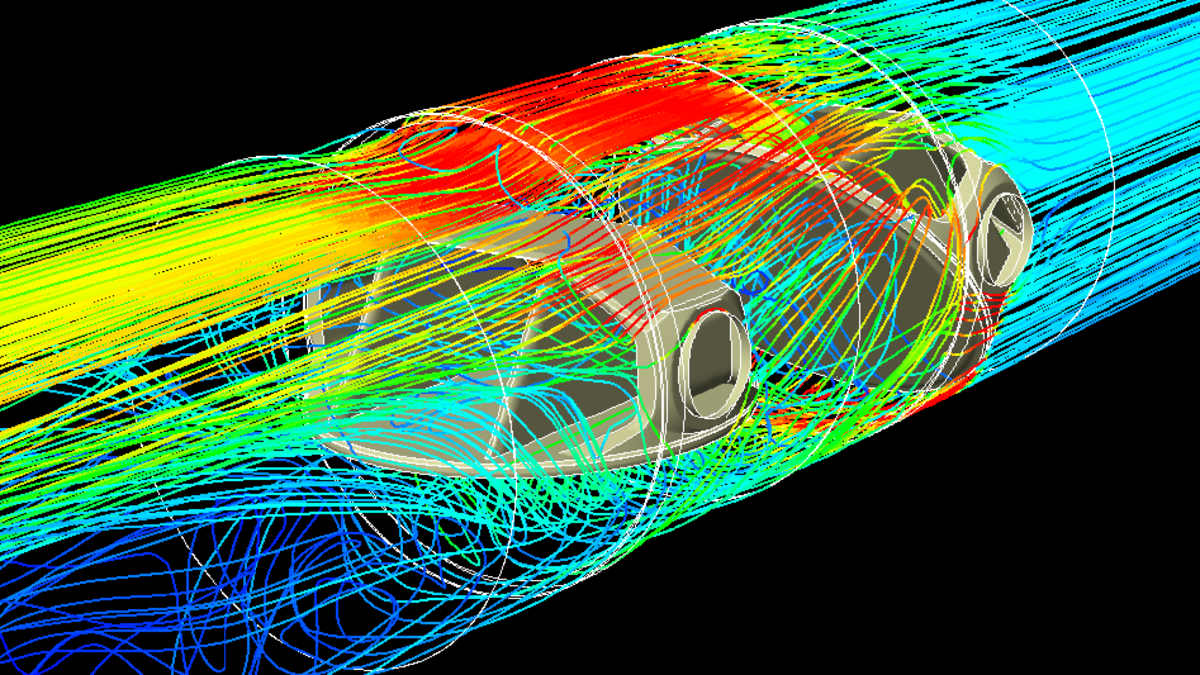

Automotive Design

Automakers rely heavily on CFD simulations for aerodynamic testing of new vehicle designs. Things like airflow around and inside a car, how smoke and exhaust disperses, and cooling performance of components can all be analyzed using CFD instead of expensive wind tunnel experiments. This has significantly reduced physical prototype development cycles.

Aerospace Engineering

The aerospace industry is another major proponent of CFD. Designing aircraft, helicopters, rockets, and satellites requires modeling propulsion, thrust, drag, lift and more – problems perfectly suited for computational fluid dynamics. CFD helps optimize designs while meeting strict performance and safety standards.

Industrial Process Design

Whether it’s the flow of chemicals in an oil refinery, gas flow in power plants, mixing processes in factories, or fluid behavior in pumps and pipes – understanding industrial processes begins with digital simulations. CFD is used at every stage from conceptual design to troubleshooting.

Biomedical Applications

CFD also aids biomedical research related to blood flow, organ functionality, prosthetics development and more. Detailed flow simulations provide crucial insights that would be impossible to retrieve experimentally. Many surgical planning procedures now rely on patient-specific CFD models.

Accuracy and Validation of CFD Simulations

While CFD allows for the virtual experimentation of fluid flows, the accuracy of results depends on properly accounting for complex physics. Some factors that influence simulation accuracy include:

Mesh Resolution

The finer the computational mesh used to discretize the problem domain, the more accurate the representation of geometric details and flow phenomena. But very fine meshes drastically increase computational costs. An optimal balance must be found.

Turbulence Modeling

Most fluid flows encountered in engineering involve turbulence – chaotic fluctuations that enhance transfer properties like heat, momentum and mass. Sophisticated turbulence models are needed to realistically capture turbulent effects.

Boundary Conditions

Specifying realistic boundary conditions for fluid properties, velocities, temperatures etc. at computational domain edges ensures a well-posed problem. Inaccurate boundary conditions lead to erroneous results.

Validation with Experiments

CFD results must always be validated against experimental data wherever possible to assess predictive capabilities and limitations. Advanced approaches use experimental data itself to help set up Computational Fluid Dynamics simulations through techniques like wind tunnel testing and flow visualization.

As computational power grows exponentially and new turbulence/physics models emerge, CFD is becoming increasingly accurate and reliable for modeling even the most complex flows. With validation, it offers a powerful virtual complement to physical experimentation.

The Future of CFD

Looking ahead, several trends point to an even broader role for computational fluid dynamics:

Data Center Modeling

With enormous energy usage in data centers, optimizing airflow management to cool servers is critical. CFD will play a key part in designing efficient next-gen facilities.

Urban Flow Modeling

Understanding dispersion of pollutants and improving emergency response relies on simulating flows through crowded city streets, across land and around obstacles.

Biological and Bio-medical Flows

Modeling blood flow, respiration, swimming of aquatic animals and more will uncover insights into biology, new treatments and prosthetics.

Machine Learning Integration

Artificial intelligence and deep learning are augmenting CFD capabilities through techniques like automated meshing, regression modeling of flows and design optimization.

Exascale Computing

Future exascale supercomputers promise to handle simulations involving trillion-cell meshes and provide granular detail even for the most intricate problems.

In conclusion, computational fluid dynamics has revolutionized how engineers and scientists understand and work with fluid flows. With continuing strides in hardware, algorithms and methods, the full potential of CFD is yet to be realized in tackling 21st century challenges.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it