The demand for reliable power is ever increasing as more industries and households use electricity for their growing needs. With such high dependence on electric power, any disturbance in the quality and supply of power can hamper operations and cause huge financial losses. To address this issue, power quality equipment play a vital role in maintaining a continuous and stable supply of electricity.

What is Power Quality?

Power quality refers to maintaining the electric power within acceptable standards for operated equipment. It encompasses voltage stability, frequency variation, harmonic distortion, power factor and other parameters. Poor power quality can occur due to faults on the power distribution system or due to issues originating from the customer’s equipment. Some common power quality issues include voltage sags, surges, interruptions, harmonic disturbances etc. It is important to monitor and mitigate such issues to ensure reliability of power supply.

Power Quality Monitoring Equipment

The first step towards maintaining good power quality is continuous monitoring of various power parameters. Power Quality Monitoring Equipment are used to measure the electric characteristics and identify any anomalies. These intelligent devices can monitor voltage, current, power factor, harmonics and many other electrical parameters. Advanced monitors also have communication capabilities to transmit real-time data to central databases over internet/intranet. This allows utilities and large power users to have a centralized view of power quality across different locations. Data from these monitors helps pinpoint problem areas and schedule corrective actions.

Harmonics Monitoring & Filters

One of the major power quality issues faced nowadays is the presence of current and voltage harmonics in the distribution system. Harmonics are distorted voltages or currents whose frequency is an integer multiple of the fundamental supply frequency. They are generated by non-linear loads such as variable speed drives, LED lights, UPS systems etc. Prolonged exposure to harmonics can cause overheating of transformers and motors. It also reduces the power factor efficiency. Harmonic filters are used to filter out unwanted harmonics. These passive or active filters detect the harmonic frequencies and isolate them from the main supply. Power quality monitoring devices with harmonic analyzers help identify sources of harmonics and effectiveness of filters.

Voltage Regulation Equipment

Proper voltage regulation is critical for equipment to operate reliably within tolerance limits. Unregulated voltage fluctuations outside acceptable ranges can cause malfunctioning, premature failures or trip protection devices. Voltage regulators such as tap changers, buck-boost transformers and voltage stabilizers are used to regulate the voltage level. Tap changers automatically adjust transformer taps to maintain the desired voltage. Static VAR compensators and capacitor banks also help support the voltage by supplying or absorbing reactive power. Voltage regulation solutions coupled with monitoring systems ensure voltage is kept within specified bandwidth under all loading conditions.

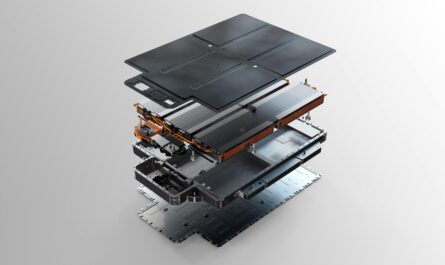

Power Conditioning Equipment

Power conditioning equipment such as UPS systems, voltage stabilizers, surge protectors etc are used to protect sensitive electronic equipment from troublesome power issues. Uninterrupted Power Supplies (UPS) provide backup power during outages through an integrated battery bank. They also filter voltage spikes/sags and offer AC voltage regulation. Voltage stabilizers regulate fluctuations and ensure a steady output. Surge protectors shield equipment from high voltage surges/spikes by shunting excess energy to ground. Other power conditioning products include isolation transformers, line reactors etc to eliminate common mode noises and improve power quality. These play a pivotal role in maintaining continuity of critical operations.

Preventive Maintenance of Equipment

To ensure long life and reliable performance of power quality equipment, periodic preventive maintenance is a must. Failing to conduct timely maintenance checks can compromise the efficiency and effectiveness over time. Maintenance activities include inspection and cleaning, thermal scanning, insulation resistance testing, calibration of sensors and equipment settings. Batteries need to be load tested and replaced as required. Harmonic filters need cleaning to remove dust accumulation. Condition assessment helps identify worn-out components for replacement. A well-planned preventive maintenance routine carried out by qualified technicians can significantly reduce equipment downtime and failures. It also helps optimize the useful life as per manufacturers recommendations.

In summary, a combination of monitoring devices, regulation solutions, filtering equipment and conditioning products ensures smooth power quality is delivered to industrial and commercial facilities. While capital investments may be involved initially, choosing reliable power quality solutions actually saves costs in the long run through increased equipment uptime and reliability. Proper implementation coupled with maintenance can help achieve business continuity even during power disturbances. Overall, maintaining clean and regulated power has become indispensable for seamless operations across various industries in the modern digital economy.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it