Market Overview:

The global digital fabrication market is estimated to be valued at US$38.01 billion in 2023, with a projected compound annual growth rate (CAGR) of 30% from 2023 to 2030. As highlighted in a new report published by Coherent Market Insights, this market offers a wide range of products that provide numerous advantages to various industries. Digital fabrication includes technologies such as 3D printing, computer-aided manufacturing, and computer numerical control, which enable businesses to create custom-designed products with high precision and speed. This market addresses the need for cost-effective, efficient, and sustainable manufacturing processes across several sectors, including automotive, aerospace, healthcare, and consumer goods.

Market Key Trends:

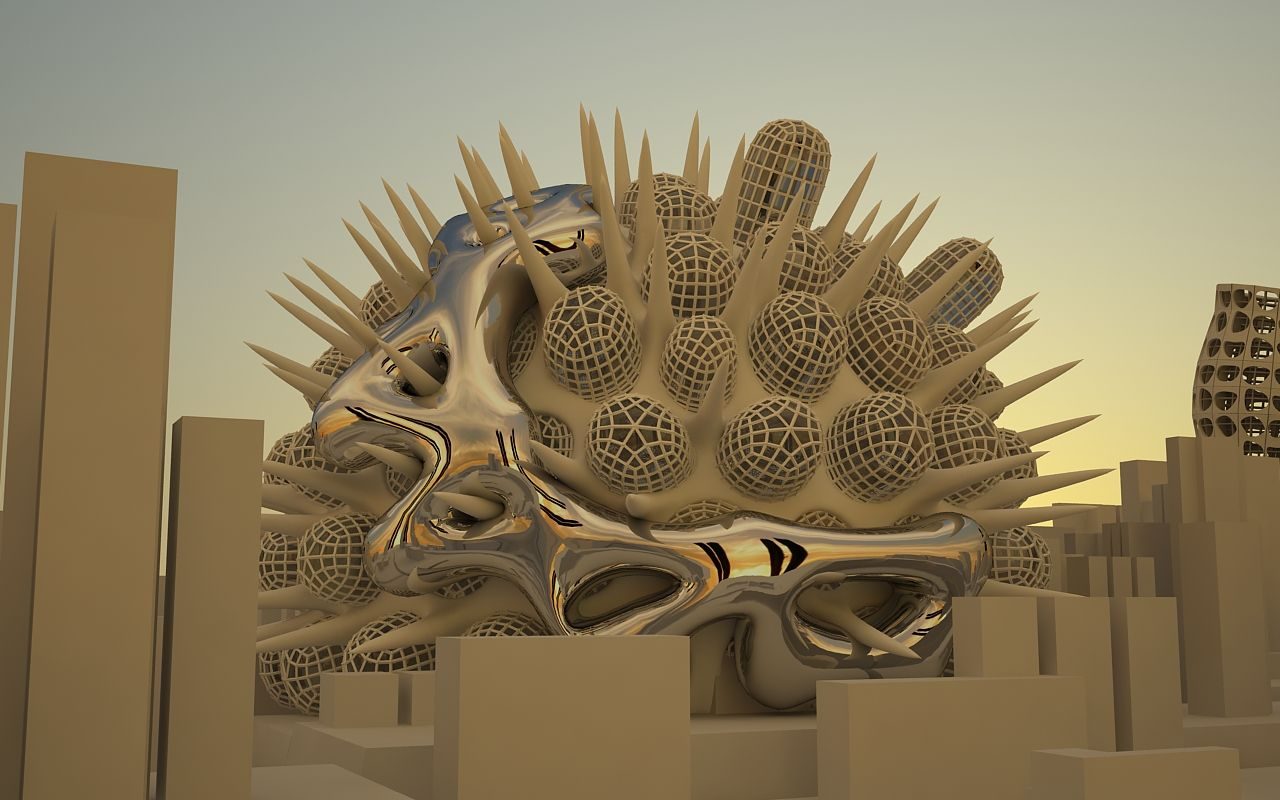

One key trend driving the digital fabrication market is the increasing adoption of additive manufacturing, particularly 3D printing, across diverse industries. Additive manufacturing allows for the production of complex shapes and designs with minimal material waste. For example, in the aerospace industry, 3D printing enables the creation of lightweight components with intricate geometries, leading to improved fuel efficiency and reduced carbon footprint.

Porter’s Analysis:

Porter’s Five Forces analysis provides insights into the competitive landscape of the digital fabrication market:

1. Threat of New Entrants: The threat of new entrants is moderate due to the high initial investment required for setting up digital fabrication facilities and the presence of established players. Additionally, intellectual property rights and proprietary technologies act as barriers to entry.

2. Bargaining Power of Buyers: Buyers have moderate bargaining power as they have access to a wide range of digital fabrication service providers. However, the quality, speed, and cost-effectiveness are vital factors considered by buyers while choosing suppliers.

3. Bargaining Power of Suppliers: Suppliers of digital fabrication technologies and materials have significant bargaining power due to their expertise and control over the supply chain. This power increases if there are limited suppliers of specific technologies or materials.

4. Threat of New Substitutes: The threat of substitutes in the digital fabrication market is relatively low. Traditional manufacturing methods often lack the flexibility, speed, and cost-effectiveness offered by digital fabrication technologies.

5. Competitive Rivalry: The Digital Fabrication Market Growth is highly competitive, with several key players striving to gain market share. Continuous technological advancements, product innovation, and strategic collaborations are common strategies employed by players to maintain their competitive edge.

Key Takeaways:

– The global digital fabrication market is expected to witness high growth, exhibiting a CAGR of 30% over the forecast period, driven by the increasing adoption of additive manufacturing technologies.

– North America is projected to dominate the digital fabrication market due to the presence of key players, advanced technological infrastructure, and high adoption rates across industries.

– Stratasys Ltd., 3D Systems Corporation, HP Inc., General Electric Company, Materialise NV, and Proto Labs Inc. are among the key players operating in the global digital fabrication market. These players leverage their expertise to offer a diverse range of solutions and maintain their market position.

In conclusion, the digital fabrication market is poised for substantial growth in the coming years, driven by technological advancements, the need for customization, and cost-effective manufacturing processes. With additive manufacturing technologies at the forefront, businesses across various sectors are embracing digital fabrication to enhance their operational efficiency and deliver innovative products to meet evolving customer demands.