Introduction

Geopolymer is an innovative material that has the potential to revolutionize the construction industry by providing a more sustainable alternative to traditional cement. This article will explore what geopolymers are, how they are made, their advantages over concrete, and real-world applications.

What are Geopolymers?

Geopolymers are aluminum-silicate materials formed through a chemical reaction between an alkaline activator such as sodium hydroxide or potassium hydroxide and aluminosilicate materials like clay or metakaolin. The geopolymerization process consists of dissolving soluble silica and alumina species from the source material into an alkaline solution, followed by a polycondensation reaction which results in a three-dimensional, hardened inorganic polymer. In simpler terms, geopolymers are man-made stones created through a chemical process rather than needing extreme heat and pressure over millions of years like natural igneous rocks.

Geopolymer raw materials

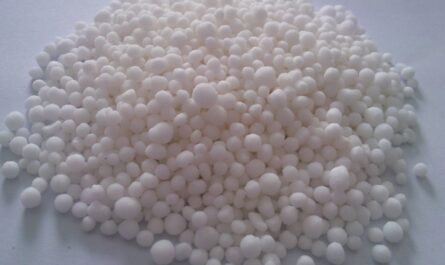

The key raw materials required for Geopolymer production are aluminosilicate rocks and an alkaline activator. Common aluminosilicate sources used include fly ash, metakaolin, slag, and natural pozzolans like calcined clays. Fly ash is the most widely used due to its low cost and wide availability, and metakaolin is popular because it has high reactivity. The alkaline activators are usually a combination of sodium or potassium hydroxide, silicate solutions, or a mixture of both. Water is also needed as the reaction medium. Careful selection and proportioning of raw materials is important in controlling the polycondensation reaction and resulting properties.

Advantages over traditional cement

Geopolymers offer several advantages over traditional Portland cement based materials:

Embodied energy – Geopolymers have up to 80% lower embodied energy compared to ordinary Portland cement due to avoiding the energy-intensive calcination process required for cement production.

Emissions reductions – Producing geopolymers results in up to 80% less CO2 emissions than cement. This is because aluminosilicate source materials like fly ash are byproducts from coal combustion that would otherwise be waste materials.

Chemical resistance – Geopolymers have a lower pH of around 12-13 compared to cement’s high pH of 13, making them more chemically durable in conditions involving acids, alkalis or other corrosive substances.

Fire resistance – Geopolymers react endothermically at elevated temperatures and have shown improved fire resistance over concrete. This makes them promising for applications like cladding, coatings, fireproofing and refractory materials.

Applications of Geopolymers

With their advantages, geopolymers are finding increasing applications as an eco-friendly alternative to cement based materials:

Construction – Geopolymers can be used for most construction applications that utilize concrete such as roads, bridges, foundations, precast construction blocks etc. Their durability is especially useful for transportation infrastructure exposed to weathering.

Waste encapsulation – Due to their chemical stability, geopolymers are suitable binders for stabilizing toxic waste and contaminated soils, enabling safe storage, transportation and landfilling.

Refractory materials – High temperature properties make geopolymers an effective alternative to traditional refractory cements and plasters for linings in furnaces, boilers and other heat intensive applications.

Coatings – Geopolymer coatings are being researched for applications such as sewer system rehabilitation through spray-on coatings, waterproofing membranes and tile grouts.

Nuclear waste management – Some research efforts aim to utilize geopolymers for immobilizing high-level nuclear wastes in a stable solid matrix through a process called geopolymerization encapsulation.

Barriers and future directions

While geopolymers show great promise, some practical barriers remain before widespread adoption can be achieved:

Standardization – Standard test methods and specifications are still lacking compared to established standards for Portland cement and concrete.

Setting behavior – Geopolymers normally have fast setting reactions and working times compared to cement which can limit fresh state workability for some applications.

Cost – Currently geopolymer production can be more expensive than cement due to economies of scale and feedstock availability limitations. However, costs are expected to decrease with optimization and increased utilization of waste-based aluminosilicate feedstocks.

Overall however, ongoing research continues expanding the knowledge base around geopolymer materials science while efforts towards commercialization address barriers to standardization and cost reduction. With their compelling sustainability benefits, geopolymers have strong potential to be part of the global transition to net zero carbon construction provided continued advancements are enabled.

In summary, geopolymers provide a promising alternative to traditional Portland cement based to their reduced environmental impacts through lower embodied energy and CO2 emissions, as well as advantages in chemical stability and fire resistance. While further development is still underway, innovative applications and the advantages of geopolymers have potential to significantly contribute to sustainability goals in infrastructure, waste management and other industries reliant on cementitious materials. With continued research and commercialization efforts, geopolymers could transform the building materials sector into a more eco-friendly future.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it