Thermal insulation refers to materials used and methods employed to slow down or reduce the transfer of heat between two objects or spaces, thus preventing heat loss or gain. Thermal insulation plays a key role in keeping objects at desired temperatures whether hot or cold, by regulating the flow of heat. Some common applications include insulation of buildings from outside temperature extremes, insulation of industrial equipment and pipes, insulation in clothing, footwear and thermos flasks.

Importance of Thermal Insulation Materials

Thermal insulation is important for both energy conservation as well as human comfort. Proper insulation helps reduce energy costs for heating and cooling buildings and equipment. It also makes the indoor environment more comfortable by maintaining a relatively stable temperature inside. Thermal Insulation Materials is vital in certain scientific and medical applications where regulated temperatures are essential like incubators, refrigeration systems and thermostats. Insulation ensures the even distribution of heat and prevents localized overheating or cooling. It protects people and equipment from surface temperatures that are too hot or cold. Overall, insulation plays a significant role in energy efficiency.

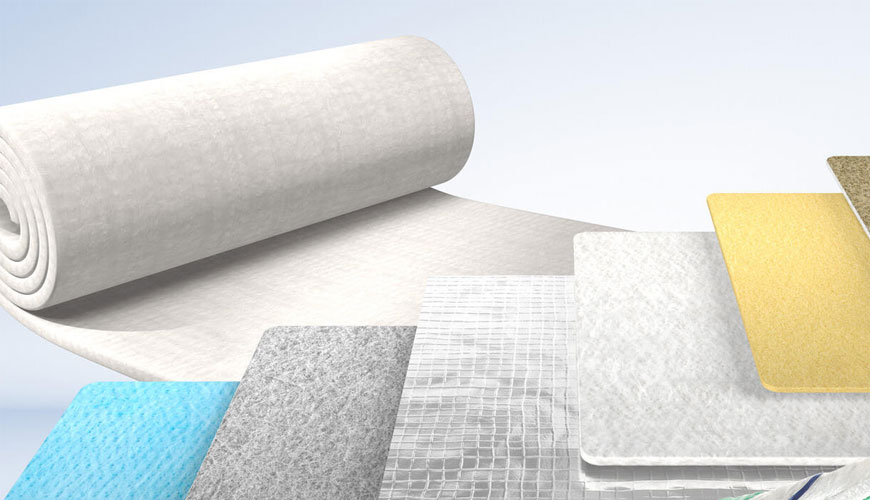

Common Thermal Insulation Materials

There are various materials used for thermal insulation depending on the application and required insulation properties. Some of the major Thermal insulation materials are:

Mineral Wool: Mineral wool like fiberglass and stone wool are synthesized from inorganic materials and are spun into coarse fibers. They are non-combustible and retain their insulating properties even at high temperatures. Mineral wool is widely used for insulation of building structures, pipes, ducts and industrial equipments.

Plastic Foams: Polyurethane foam (PUF), extruded polystyrene foam (XPS) and expanded polystyrene foam (EPS) are common plastic foams used for insulation. They are highly effective insulators with closed-cell structure that traps air pockets. Plastic foams provide high insulation at relatively low thicknesses. They are moisture resistant and inexpensive insulation choice.

Cellulose Insulation: Cellulose insulation is made from 80-90% recycled newspaper fibers treated with boric acid for fire resistance. It is widely used in walls, ceilings and floors of residential buildings. Being hydrophilic, cellulose insulation absorbs moisture easily and molds easily if wet.

Glass Wool: Glass wool is a synthetic spun fiber made from molten glass and is less harmful than other mineral wools. It is odourless, moisture resistant, and non-irritant to skin. Glass wool insulation is flexible and used for domestic central heating systems, roof spaces and lofts.

Aerogels: Aerogels are highly porous solid materials created from gel where the liquid component of the gel is replaced with gas. Silica aerogel is exceptional thermal insulator with porosity over 90% offering low thermal conductivity. However, high production costs restrict its common usage.

Refractory Ceramic Fibers: These synthetic vitreous fibers are extremely durable and heat resistant up to 1100°C. They are used in high-temperature insulation applications in the steel, petrochemical and power generation industries. RCFs are considered carcinogenic if inhaled in fiber form.

Advantages and Disadvantages of Common Insulation Materials

Mineral Wool: Durable, low cost, handles moisture well, fire-resistant but can cause itching.

Plastic Foams: Lightweight, moisture resistant, easy to install but may release toxic gases if burnt.

Cellulose: Renewable, cost-effective, handles moisture well but prone to mold growth if wet.

Glass Wool: Non-combustible, resilient to moisture, low cost, but irritating fibers.

Aerogels: Exceptional insulator but very expensive to produce.

Refractory Ceramic Fibers: Very heat resistant for high-temperature applications but a known carcinogen.

The choice of insulation material depends on factors like thermal properties required, budget, installation method, life expectancy, fire safety standards and insulation thickness constraints. A judicious combination of different insulating materials may often provide the best insulation solution. Proper installation is equally important for insulation to deliver its rated performance over long years. Regular maintenance and checks also ensure sustained insulation benefits.

Promoting Sustainable Thermal Insulation Materials

With growing global focus on energy conservation and reducing carbon footprint, adoption of sustainable thermal insulation is need of the hour. Recycled and bio-based materials like cellulose and sheep’s wool offer renewable insulation options. Phase change materials (PCMs) and vacuum insulation panels (VIPs) utilizing nano-encapsulated PCMs provide high insulation with small thickness. Insulating concrete forms (ICF) made of polystyrene blocks provide monolithic insulation in building structures. Reflective radiant barrier foils are effective reflective insulation substitutes. Advances in insulation also involves vacuum insulation, aerogel-impregnated insulation, super-insulating glass, vacuum glazing, vacuum insulation panels and fibreglass. Proper application of suitable sustainable insulation can significantly lower energy bills and carbon emissions over building lifecycles.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research.

2. We have leveraged AI tools to mine information and compile it.