Indium Gallium Zinc Oxide, commonly referred to as IGZO, is an emerging technology that is poised to revolutionize the electronics industry. This novel semiconductor material offers significant advantages over traditional silicon and is already finding its way into many consumer products. Let’s take a deeper look at IGZO technology and explore where it is heading.

What is IGZO?

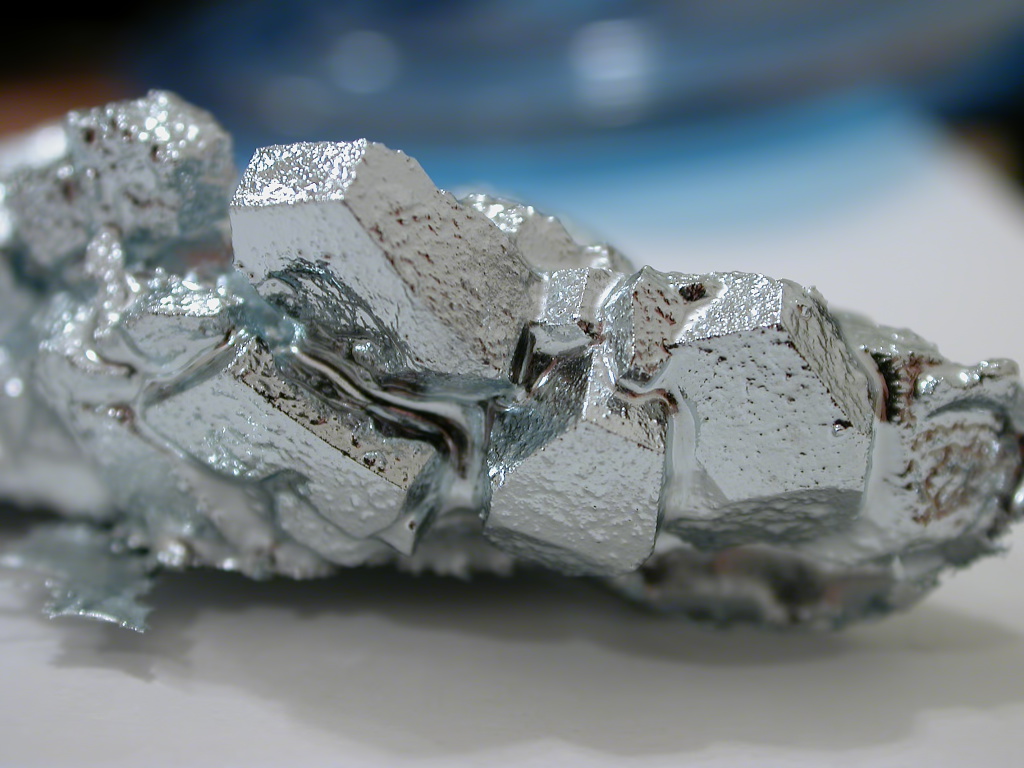

IGZO is a technology based on a crystalline oxide semiconductor composed of indium, gallium, zinc, and oxygen. When deposited as a thin film and processed, it exhibits properties that make it a viable alternative to amorphous silicon for applications such as thin-film transistors (TFTs). IGZO offers higher electron mobility compared to amorphous silicon, enabling the development of devices with faster switching speeds and lower power consumption.

IGZO was first commercialized in 2011 and is currently used primarily in high-resolution LCD displays for small/medium sized devices such as smartphones, tablets, and laptops. By replacing amorphous silicon, IGZO allows for the miniaturization of pixel sizes which results in sharper images and higher pixel densities without sacrificing performance or increasing power usage. This advantage makes it an attractive option for any device requiring a high-resolution display with lower power needs.

Applications in High-Resolution Displays

The first major application of IGZO was in Apple iPad displays starting from the third-generation iPad launched in 2012. Other manufacturers soon followed and IGZO quickly became the preferred technology for tablets and high-end smartphones seeking ultra-sharp “Retina-class” displays.

By 2015, nearly all flagship Android devices were using IGZO LCD or AMOLED displays. Even budget phones started incorporating IGZO to achieve higher resolutions at more affordable price points. Today, virtually every tablet and most high-to-mid-range smartphones utilize IGZO technology in their LCD panels, enabling them to pack more pixels in without hurtting battery life.

IGZO is also enabling the development of new form factors like foldable or rollable displays thanks to its robustness and flexibility. Devices like the Samsung Galaxy Z Fold3 rely on IGZO to allow for dynamic display shapes without sacrificing on-screen performance. As foldable/rollable displays become mainstream, IGZO will play a vital role in powering this next generation of uniquely designed consumer electronics.

Potential in Other Applications

While displays remain the biggest use case currently, IGZO’s inherent properties open up possibilities in several other applications as well. Its high mobility, transparency, and lower thermal budget make it a suitable candidate for:

– Radio-frequency identification (RFID) tags: IGZO’s properties allow for thinner, more efficient RFID tags for uses like supply chain tracking.

– Printed/flexible electronics: Depositing IGZO as an ink enables fully printed/flexible circuits for novel form factors like bendable displays or conformal biosensors.

– Memory applications: Experimental IGZO memory devices have shown potential to enable higher-density NAND flash chips for data storage.

– Sensors: The material’s transparency provides avenues to develop see-through imaging sensors for augmented reality applications.

With further material optimization and scaling, IGZO could displace silicon in additional areas that prioritize attributes like thinness, flexibility, power efficiency and transparency over raw switching speeds. This promises to open exciting opportunities across consumer electronics, healthcare, automation and more.

Expanding Production and Beyond Moore’s Law

Initially, just a handful of manufacturers like Japan Display were producing IGZO for a limited set of customers. However, as the technology has matured and demand grown exponentially, many global firms are now aggressively ramping up their IGZO manufacturing capabilities.

In 2020, companies like LG Display, BOE, Sharp,Visionox and others had all unveiled plans for new dedicated IGZO production lines. Taiwan Semiconductor Manufacturing Co (TSMC) even started exploring volume production of IGZO for applications beyond displays. This expansion aims to meet the colossal needs of the display industry but also enable wider adoption across other domains.

With continued scaling, IGZO could help extend Moore’s Law and fuel further miniaturization of devices beyond what silicon can offer alone. The material opens new dimensions to keep advancing performance within power and space constraints – critical factors as electronics permeate every aspect of modern lives. IGZO is truly redefining the material boundaries of semiconductor technology.

IGZO’s ongoing commercialization journey promises to unlock transformative product experiences for consumers worldwide. As applications and manufacturing volumes rise in tandem, this innovative oxide semiconductor is poised for a starring role powering next-generation experiences across industries. The rise of IGZO technology has only begun.